By closely checking the process, probable issues is usually resolved proactively, reducing the chance of item non-conformities and making certain consistent solution high-quality.

This method emphasizes the value of a existence cycle solution, which begins with process layout and carries on through process qualification and ongoing process verification.

During the process style stage, it is actually essential making sure that all components of the process are totally understood and documented. This incorporates not simply the technical requirements but will also the potential effects of assorted components around the process general performance.

The process validation lifecycle consists of three stages: process style and design, process qualification, and continued process verification. Let us take a better take a look at Every of those stages:

Process validation might be outlined as the documented evidence that establishes a higher degree of assurance that a particular process will continuously produce a product that meets its predetermined specs and good quality qualities.

This really is conducted in a product now distributed based on gathered details of output, testing and Command.

Attention to element: Precision in executing validation protocols and documenting benefits is important for compliance and top quality assurance.

In this stage, the process is developed and documented intimately. The essential process parameters and the corresponding running ranges are discovered.

From the extremely regulated and quick-paced earth of manufacturing, excellent Management is of utmost relevance. Providers ought to be sure that their processes are responsible, dependable, and effective at continuously generating products that meet up with the highest criteria. here This is when process validation comes into play.

Process validation offers a multitude of benefits which will considerably increase your small business operations and item results. Here’s the way it can make a variation:

Versions in batch sizing ought to be justified to make sure that they don't adversely have an effect on the essential high quality attributes of the finished solution.

Standardize techniques: Creating and adhering to standardized procedures guarantees regularity across all validation functions. By building detailed protocols, you limit variability and make sure just about every staff member follows a similar methods.

Process style: Acquiring the process depending on know-how gained by means of growth and scale-up things to do.

Re-validation will be the process of website repeating process validation to make certain that any changes created in the process or equipment, as per improve Handle strategies, will not negatively impact the process traits and products excellent. This really is critical mainly because modifications can probably alter the product or service’s efficacy, basic safety, and top quality.

Neve Campbell Then & Now!

Neve Campbell Then & Now! Scott Baio Then & Now!

Scott Baio Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Danielle Fishel Then & Now!

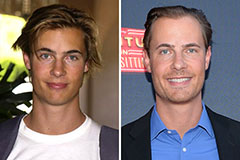

Danielle Fishel Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now!